In modern industrial environments, latch lock handle, as an essential part of safety lock control, play a crucial role in ensuring equipment safety and enhancing work efficiency. Their applications span across manufacturing, logistics, transportation, and other sectors, effectively preventing accidental openings and ensuring the normal operation of equipment. This article shengjiu will explore the advantages of latch lock handles in industrial lock control in depth.

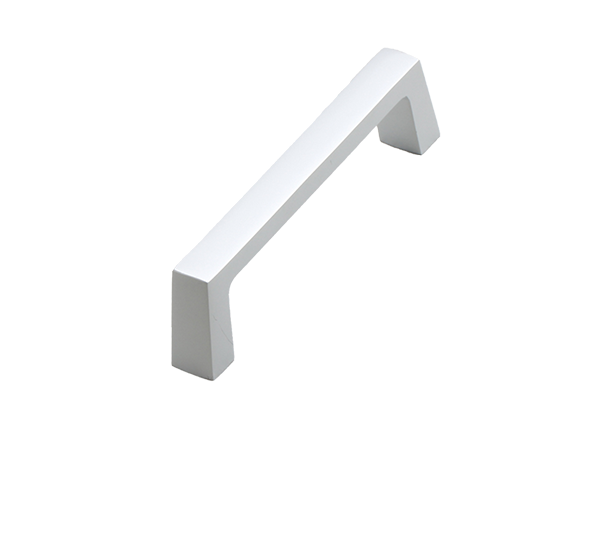

What is a Latch Lock Handle?

A latch lock handle is a mechanical device designed for industrial lock control, widely used in cabinets, distribution cabinets, control boxes, and other equipment that require high safety and convenient operation. It controls the opening and closing of door panels or cover panels by rotating or pulling the handle, enabling fast and stable locking and release operations. Latch lock handles are typically made from high-strength materials, featuring corrosion resistance and wear resistance to meet the demanding requirements of industrial environments. Their high durability and effective sealing ensure the safety and stability of the equipment, reducing failures caused by accidental openings or corrosion. Furthermore, latch lock handles come in a variety of designs to meet the specific needs of different industrial scenarios, making them essential components in industrial lock control systems.

Advantages of Latch Lock Handles in Industrial Lock Control

The extensive use of latch lock handles in industrial lock control systems is primarily due to their excellent durability and reliability, ensuring efficient operation in complex and changing industrial environments. The following outlines the main advantages of latch lock handles in industrial lock control.

Enhancing Safety

In industrial production processes, many pieces of equipment and containers contain hazardous substances or high-speed moving parts, making it crucial to prevent unintentional openings or mishandling. Latch lock handles provide a high level of safety for industrial equipment through stable mechanical locking. High-quality latch lock handles can effectively withstand external impacts while maintaining a locked state, thus preventing accidents caused by inadvertent operations. Additionally, with advancements in smart lock technology, some high-end latch lock handles come equipped with electronic monitoring features, providing real-time feedback on the locking status to enhance overall safety. This integrated security measure significantly improves equipment protection against tampering and safeguards essential equipment and production processes.

Improving Operational Efficiency

In industrial environments, production efficiency improvements often rely on reducing unnecessary operation time. The design of the latch lock handle prioritizes operational convenience, typically allowing users to lock or unlock through simple rotations or push-pull actions. This design greatly simplifies the operation process, reducing operator workload. For high-frequency switching scenarios, latch lock handles with quick-lock functions can complete the locking process instantly, further boosting work efficiency. Additionally, latch lock handles integrated with automation systems enable remote equipment control, reducing manual operation time and enhancing the overall production flow.

Resilience in Harsh Environments

Industrial environments subject latch lock handles to dust, high temperatures, humidity, vibration, and other challenging factors. High-quality latch lock handles are often specially treated to ensure waterproof, dustproof, and corrosion-resistant properties. Even when used continuously in harsh environments, they can maintain stable performance. In extreme environments such as petrochemical and mining industries, latch lock handles with high protection levels not only extend their service life but also reduce failure rates and maintenance costs. The casings of many high-end latch lock handles undergo protection-level testing to withstand various environmental challenges, ensuring reliability in diverse industrial applications.

As a critical component in industrial lock control, the latch lock handle has become an indispensable part of many industrial scenarios due to its reliable locking function and outstanding durability. Selecting the appropriate latch lock handle and maintaining it properly in daily use can improve both equipment safety and production efficiency. As industrial lock control systems grow increasingly complex, the key role of latch lock handles becomes even more prominent, providing a strong safeguard for the safety and efficiency of industrial production. Through a deeper understanding and appropriate application of latch lock handles, companies can better manage equipment safety and enhance production efficiency. In the future, with technological advancements, the trend toward intelligent and automated latch lock handles will make their role in industrial lock control systems even more critical.