01 Abstract

The phase change heat transfer technology represented by heat pipes and VC (Vapor Chamber) has much higher thermal conductivity than traditional materials and is a key technology to solve the growing demand for product heat dissipation.

In recent years, aluminum VC radiators have become one of the research hotspots in the industry. The research and application of aluminum VC heat sinks are in line with the development trend of high-performance, lightweight, and low-cost communication products in heat dissipation, and are of great significance. Therefore, Shengjiu Group and ZTE Communications have conducted breakthrough research on all aluminum VC heat sinks.

02 The advancement of radiator technology

Heat dissipation is an important link in ensuring the long-term safe and reliable operation of electronic devices and products. As the field with the most intensive application of heat consuming devices such as chips, the development of communication and information technology has promoted heat dissipation or thermal design to become a systematic industry. Research and development in fields such as power, security, consumer electronics, automobiles, and LEDs are also increasingly focusing on the heat dissipation performance of products, in order to have more advantages in market competitiveness.

Currently, 5G communication and information products are developing towards the goal of larger capacity, higher performance, energy conservation, and low noise. The degree of device integration is increasing, and single chip functions are becoming more powerful, resulting in a significant increase in power consumption. However, the layout is becoming more compact, and the heat flux density is increasing exponentially. Cooling technology is facing severe challenges.

Traditional heat dissipation systems mainly rely on single-phase material to conduct heat from the device to the surface of the radiator, and then the heat is dissipated into the environment by air through natural convection (natural heat dissipation system) or forced convection (forced air cooling system). The efficiency of heat conduction depends on but is also limited by the inherent thermal conductivity of the material.

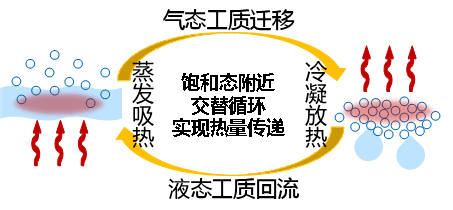

The phase change heat transfer technology represented by heat pipes and VC (Vapor Chamber) utilizes the medium to boil in the high-temperature region (heat source region) and condense in the low-temperature region, while absorbing or releasing the corresponding latent heat of phase change, alternating circulation, and achieving rapid diffusion or migration of heat. The absorption and release of latent heat is a rapid and efficient process, and when using two-phase heat transfer, working fluids with higher latent heat are usually chosen, resulting in extremely high heat transfer efficiency. The equivalent thermal conductivity can reach 4000 W/m · K or more, far exceeding pure metal materials such as gold, silver, copper, and aluminum (200-400 W/m · K), and can support higher power consumption and heat flux density heat transfer needs that traditional heat sinks cannot meet. At the same time, it can be matched with various forms of cold sources (natural convection, forced air cooling, liquid cooling, radiation, etc.), and its application forms are flexible and diverse.

Figure 1 Principle of Phase Change Heat Transfer

At present, the two-phase heat dissipation components have evolved from the earliest proposed and widely used heat pipes to various forms such as VC soaking plates, 3DVC heat sinks, Thermosyphon heat siphons, LTS loop heat siphons, LHP loop heat pipes, etc. The shell materials have also expanded from traditional copper materials to aluminum, titanium, stainless steel, etc., to meet the requirements of different application scenarios.

Figure 2 Morphology of Different Two Phase Heat Dissipation Components

03 Development of Aluminum VC Radiator Technology

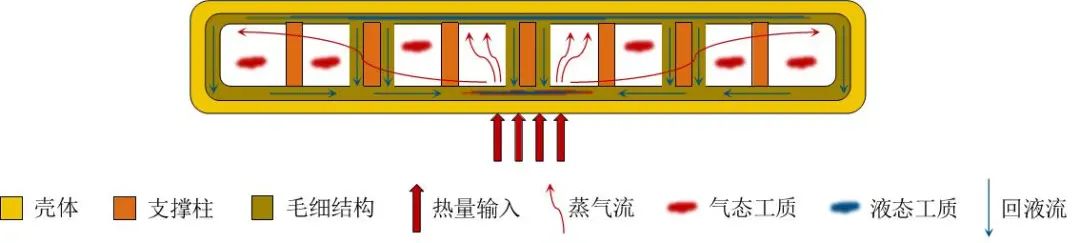

VC soaking plate is currently the most mature phase change heat transfer product in terms of technology besides heat pipes, and is widely used in the communication and electronics industries. A typical VC is a flat closed form, consisting of a shell, capillary structure, support structure, and working fluid. Efficient heat conduction is achieved through the evaporation, condensation, and capillary transport of the working fluid, diffusing heat from the concentrated area to the entire structural plane. Thanks to the advantages of large-area capillary properties and two-dimensional or even three-dimensional thermal diffusion, VC has a higher heat flux density carrying capacity. Especially for electronic devices with a heat flux density exceeding 50W/cm2, the uniform temperature effect is significantly better than that of pure metal or embedded heat pipe cooling substrates, which can greatly improve the efficiency of heat sinks.

Figure 3 Structural principle of VC soaking plate

The shell of VC is usually made of metal materials, including copper, titanium, aluminum, stainless steel, etc. Due to the good thermal conductivity, mechanical processing and welding properties of copper materials, the forming process is relatively simple and the accuracy is high. Currently, the vast majority of VC is made by stamping copper thin sheets. In the military or aerospace fields, in order to achieve lightweight, aluminum is usually used as the shell material for VC. In recent years, in order to meet the market demand for cost reduction and weight reduction, exploration of aluminum VC radiators has gradually been carried out in the field of civil heat dissipation. The research focuses mainly on the design of the suction core structure, welding technology, and internal working fluids.

(1)Research on Aluminum VC Liquid Absorbing Structure

VC mainly relies on the internal suction core structure to provide the power for condensate reflux, which will affect the critical heat flux and thermal performance of VC. At present, the common liquid absorbing core structures of aluminum VC in the industry are mainly divided into two categories: micro groove type and multi hole type.

①Micro groove type

The micro groove liquid suction core is made by machining small grooves on the inner wall of VC, and utilizes the tension of the groove interface to reflux the liquid working medium and achieve the function of the liquid suction core. With the development of micro groove suction core preparation technology, scholars have prepared various shapes of micro grooves, and common micro groove structures are shown in Figure 4.

Figure 4 Common Microgroove Structures

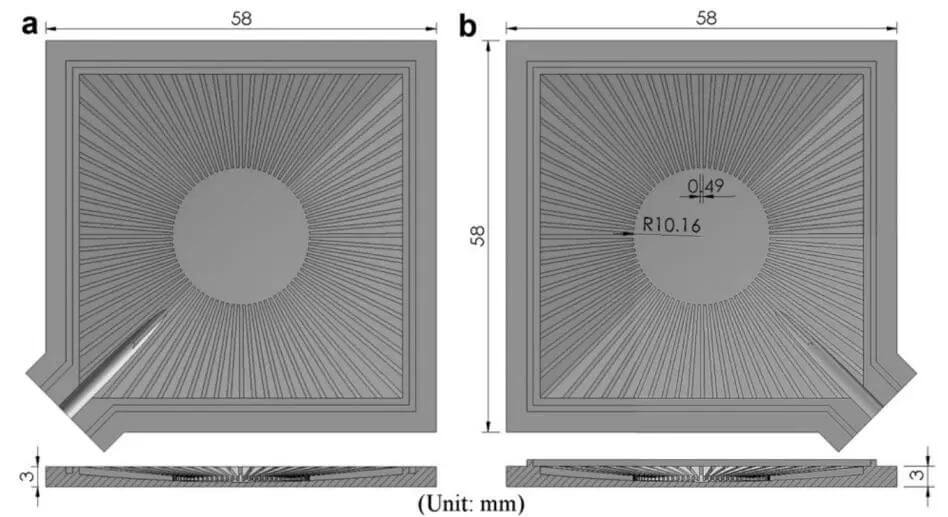

Chen et al. conducted a study on radial groove core aluminum VC and compared it with sintered aluminum powder aluminum VC. The test results indicate that the thermal resistance performance of sintered aluminum powder aluminum VC is more stable than that of radial groove core aluminum VC.

Figure 5 Radial groove core aluminum VC radiator

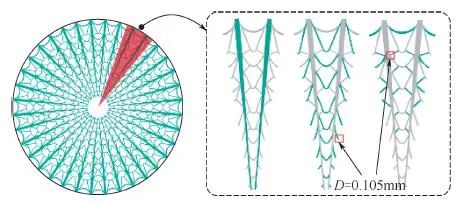

In order to solve the problem of limited heat transfer caused by the small capillary limit of the micro groove suction core, many new structures have been developed on the basis of common micro grooves. Li et al. divided the disk into a series of identical fan-shaped regions and developed a micro groove structure with branches based on leaf vein structure. Compared with conventional micro grooves, this structure has better overall temperature uniformity in VC.

Figure 6: Vein shaped micro groove structure

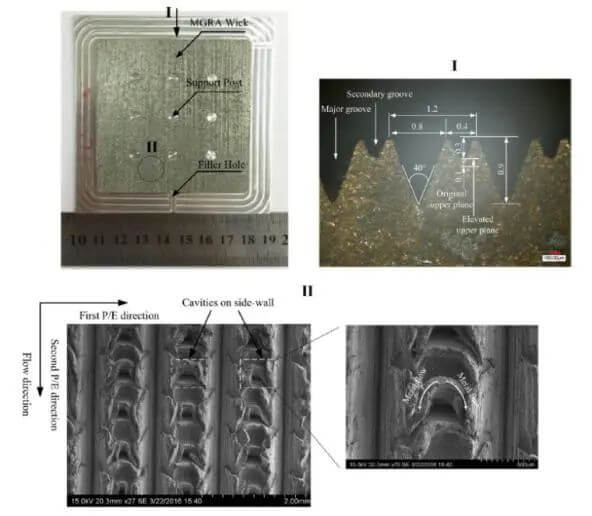

Zeng et al. processed high aspect ratio grooves on aluminum plates using a plowing extrusion process. At the same time, through bidirectional cutting in both horizontal and vertical directions, an array cavity structure is machined on the basis of the groove, further enhancing the capillary force of the suction core.

Figure 7: Plow cut extruded groove aluminum VC surface

②Porous type

Sintered powder suction core has the advantages of light weight, large capillary force, large specific surface area, heat resistance and corrosion resistance, and is widely used in copper VC. However, the application of this technology on aluminum powder is relatively difficult: aluminum materials are prone to forming oxide films on the surface due to their active properties, and the melting point of alumina is too high (about 2000 ℃), making it difficult to sinter. Therefore, extensive research has been conducted in academia and industry on the processing of aluminum porous structures.

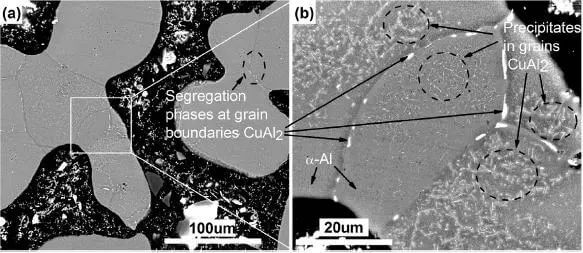

Zhang et al. achieved the sintering of aluminum powder through liquid-phase enhanced sintering. Add 4.5wt% mass fraction of copper powder to the aluminum powder and sinter for 60 minutes under the protection of 99.99% argon at 600 ℃. The copper powder forms a sintering neck between the aluminum powder, thereby forming a porous liquid absorbing core.

Figure 8 Electron Microscopy of Aluminum Powder Sintering Neck (Copper Powder Mass Fraction 3.5wt%)

Ameli M et al. manufactured aluminum porous structures using Selective Laser Melting (SLM) technology. The processing is carried out under a normal argon pressure of 14mbar, and the oxygen content in the processing room is maintained between 0.1% and 0.2%. Laser sintering is carried out layer by layer on an aluminum substrate, and the final sintered product is shown in Figure 9.

Figure 9 SLM technology sintered aluminum porous structure sample

Zhang et al. developed an aluminum fiber sintered capillary structure. Compared to aluminum powder, aluminum fibers form a large number of burrs at the edges when flowing out of the tool, which can improve the specific surface area and bonding force during the sintering process.

Figure 10 Aluminum fiber processing process and sintered finished products

In summary, due to the active nature of aluminum material and its tendency to form oxide films, the first approach to processing high-quality capillary cores is to avoid sintering processes and use mechanical means to process the capillaries; The second approach is to reduce the difficulty of sintering by protecting the atmosphere and increasing the formation point of the sintering neck (by adding other metals or increasing contact points). However, overall, these processing methods are difficult, inefficient, and costly to implement in industry.

In response to this, Ningbo Shengjiu Technology Co., Ltd. has developed a new type of aluminum based liquid suction core. The liquid suction core is made of slotted ultra-thin aluminum sheets that are bent and pressed multiple times. After processing, it is fixed on the substrate by brazing. Compared to other methods, this aluminum based suction core has simple processing, low cost, and good application prospects.

(2)Research on Aluminum VC Welding Process

At present, aluminum VC is usually processed using brazing technology to complete the combination of upper and lower cover plates. However, brazing technology has disadvantages such as low weld strength, easy blockage of capillaries, and easy corrosion. Therefore, research on the connection process of aluminum VC upper and lower cover plates has also begun in the industry.

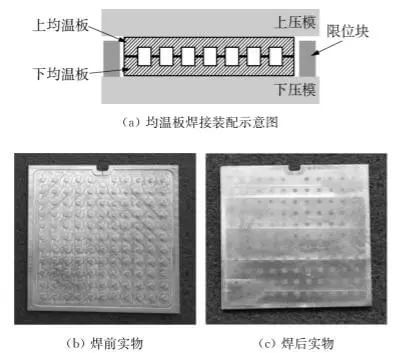

Chen Xu and others studied the diffusion bonding process of aluminum uniform temperature plates. The samples were placed in a vacuum diffusion welding furnace with a vacuum degree of no less than 5 × 10-3Pa, and the optimal process parameters were explored by loading different welding temperatures, pressures, and times. Research has shown that process parameters of 550 ℃, 3MPa, and 2 hours of insulation can optimize the weld quality of aluminum uniform temperature plates.

Figure 11 Schematic diagram of aluminum VC welding assembly and physical image before and after welding

However, the aluminum diffusion welding process requires too much vacuum degree from the vacuum furnace, and conventional vacuum diffusion welding furnaces cannot meet the requirements, which restricts the large-scale application of this process on aluminum VC radiators. The optimization of the welding process for the upper and lower cover plates of aluminum VC still requires joint efforts within the industry.

(3)Research on Internal Working Medium of Aluminum VC

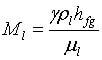

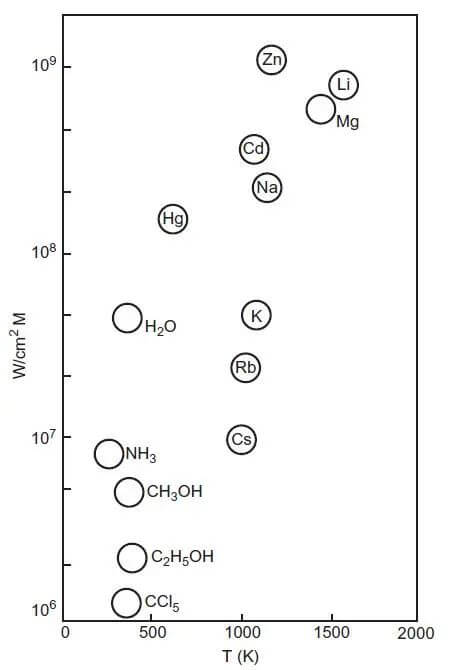

The selection of working fluid for a uniform temperature plate requires consideration of factors such as compatibility with the absorbent core and substrate materials, thermal stability, wettability, high latent heat, high thermal conductivity, and high surface tension. A quick way to measure the performance of working fluids is to compare their Merit Number. There are various definitions of quality factors, but the basic form is to integrate different thermophysical parameters into one indicator parameter. A relatively simple definition is:

After calculation and comparison, the quality factors of organic working fluids that meet the requirements of temperature range and environmental protection are not significantly different. Currently, the selection of working fluids for aluminum based two-phase radiators is largely considered from the perspective of saturated vapor pressure of the working fluid. Unlike traditional copper VC, aluminum VC is filled with organic working fluids with lower boiling points and has a positive pressure inside. When the radiator is in operation, the temperature increases and the internal pressure increases, posing a greater challenge to the pressure bearing capacity of aluminum VC. At present, the commonly used refrigerants for aluminum VC are R134A (high-pressure refrigerant) and R1233Zd (low-pressure refrigerant).

Unlike mature copper VC, aluminum VC is still in its early stages in the civilian field and requires further exploration in the industry.

04 Summary and Outlook

Aluminum VC heat sinks have become one of the research hotspots in the cooling industry due to their advantages of low cost, low weight, and high heat transfer efficiency. At present, there are still many difficulties and challenges in aluminum VC:

①The processing of high-quality aluminum based liquid absorbing cores is relatively difficult, and it is necessary to further explore more low-cost and high-efficiency aluminum based capillary structure processing methods;

②The commonly used brazing process for aluminum VC radiators currently has defects such as low weld strength, easy blockage of capillaries, and corrosion. Further research is needed to investigate the application of diffusion welding technology in aluminum VC radiators;

③The organic working fluid commonly used in aluminum VC radiators has a significant difference in surface tension and latent heat of vaporization compared to water, and further exploration is needed for working fluids with higher quality factors;

④The internal pressure of aluminum VC is positive, which is different from that of copper heat pipes and VC (negative pressure). The reliability testing standards of traditional special heat sinks are not applicable to aluminum VC, and there is currently a lack of relevant reliability testing standards in the industry. It is necessary to collaborate with multiple parties to complete the reliability testing items of aluminum VC heat sinks;

As a rising star in the field of radiators, Ningbo Shengjiu Technology Co., Ltd. has been investing heavily in the design and development of aluminum based two-phase radiators for a long time, committed to providing customers with high-quality and more cost-effective national brand choices. In the future, Ningbo Shengjiu Technology Co., Ltd. will also closely cooperate with ZTE's thermal design team to conduct in-depth exploration of the technical research and practical application of aluminum VC heat sinks, making them a sharp edge in heat dissipation technology and contributing greater strength to the development of 5G communication.

05 Epilogue

Aluminum VC heat sink, as one of the research hotspots in the industry, its research and application are in line with the development trend of communication products in heat dissipation, and have very important significance. Faced with the current difficulties and challenges of aluminum VC, Shengjiu will continue to explore in the field of heat sinks, strengthen the technical research and application of aluminum VC heat sinks, and contribute its own strength to the development of the communication industry.