A frequency converter is a power control device that uses frequency conversion technology and microelectronics technology to control the power of an AC motor by changing the frequency of the motors operating power supply. Frequency converters, like any other device,generally generate heat due to internal power loss. To ensure the normal and reliable operation of the frequency converter, it is necessary to use a fan to dissipate heat from the frequency converters At the same time full consideration should be given to the environmental factors that affect the use of frequency converters. For harsh usage environments, we must also take corresponding measures for the cooling fan to ensure the normal and reliable operation of the frequency converter.For example,frequency converters are used on CNC lathes.

Pain points in heat dissipation of CNC machine tool frequency converter Gshort service life of fan)

Due to the harsh working environment of CNC machine toolsy the fans on the frequency converter equipment are prone to oil stainsy and substances such as chip fluid can corrode the gaps ofthe fans. Different degrees of oil stains will attach to the bearings and silicon steel sheetss andthe viscosity ofthe cutting oil stains is high.After thefan runs for along time,with the increase of oil stains, itis easy to causefan failures and reduce its service life, thereby affecting the overall work efficiency of the equipment.

Implementation of solutions

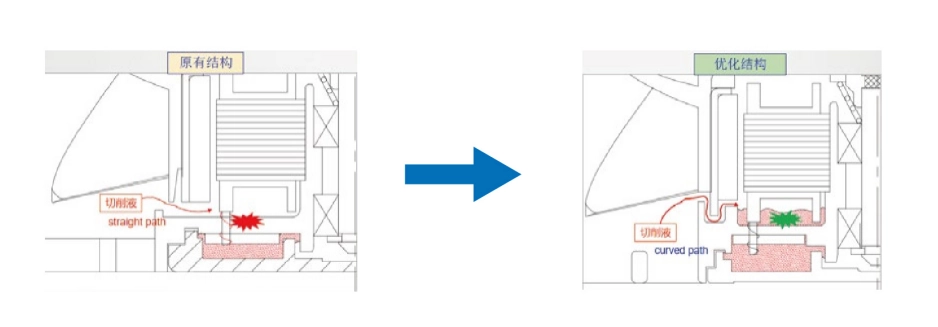

The left image shows the original structure, which adds sealing glue to the lower half ofthe motor winding area for protection. The addition of protective glue is achieved by adding a retaining wall on the inner side of the HUB of the frame At the same time the fan blades and frames are equipped with a reverse insertion and relocation structure. By changing the design ofthe frame blades and combining them to create a curved relocation structure, it is difficult for external cutting fluid to penetrate into the interiorAdditionally, filling the internal groove with sealing adhesive can effectively protect the winding connection part, while optimizing the structure.

Recommended Products for use

SD6025

SD6025

Overall Dimension:60×60×25mm

Material:impeller &Frame Plastic(Fire Rating UL94V-0)

Lead Wires:UL 10368 AWG#26 or Equivaleni

Impeller:7 Blades

Rotational direction CCW view from impeller side

Mass:80g

IP-Rating:IP68